After cutting down trees, the Logger arrives with the logs to be sold to the Log Purchaser.

The logs are unloaded into the log yard by species and length by using a log crane.

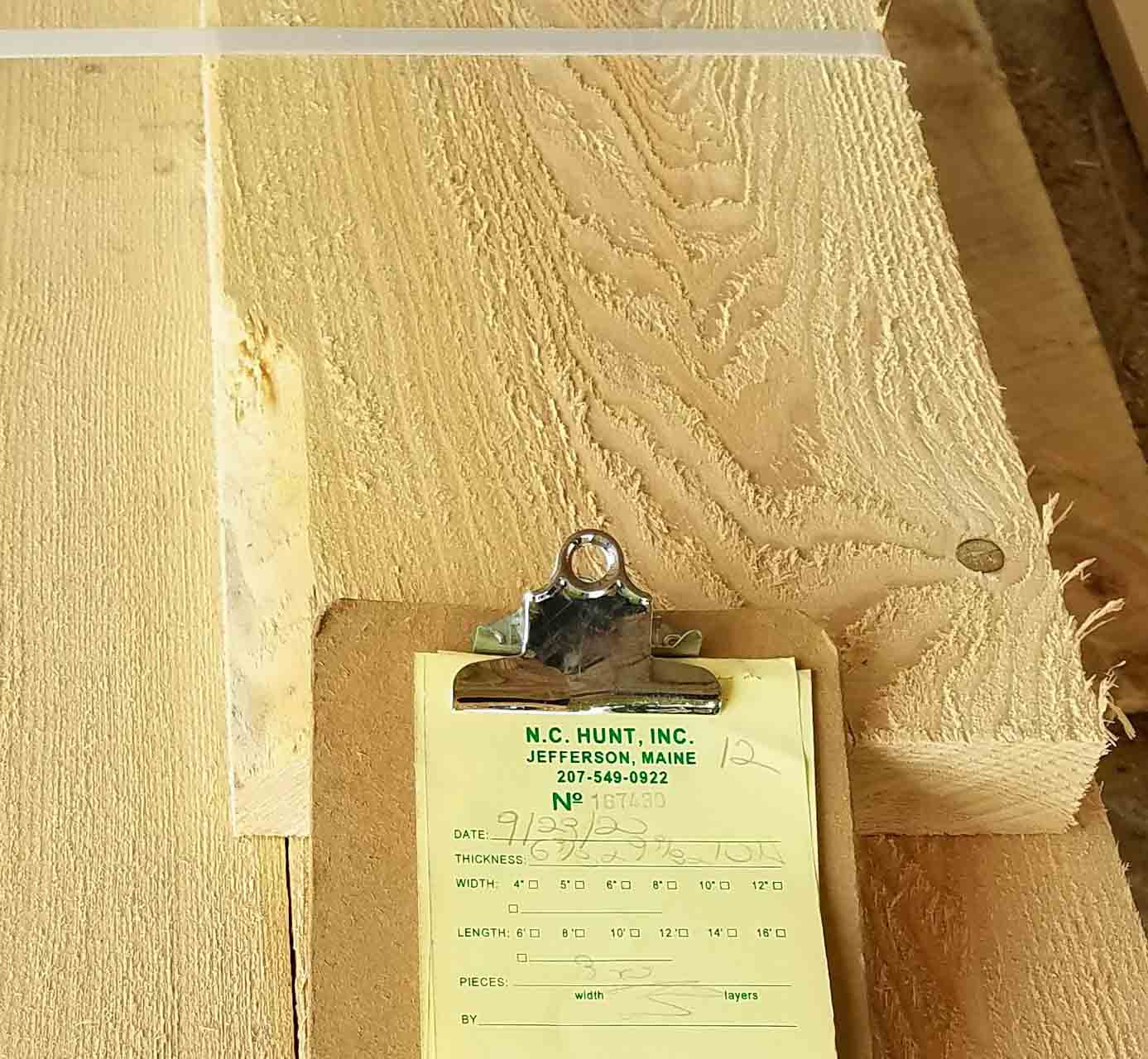

The Log Scaler measures the logs to estimate how much lumber can be made out of each log.

The Equipment Operator loads the logs onto the Debarker Log Deck.

Logs go through the metal detector to make sure there is no metal inside of the log. The Debarker will then remove all the bark from the outside of the log.

The bark that is removed from the logs is used to make mulch.

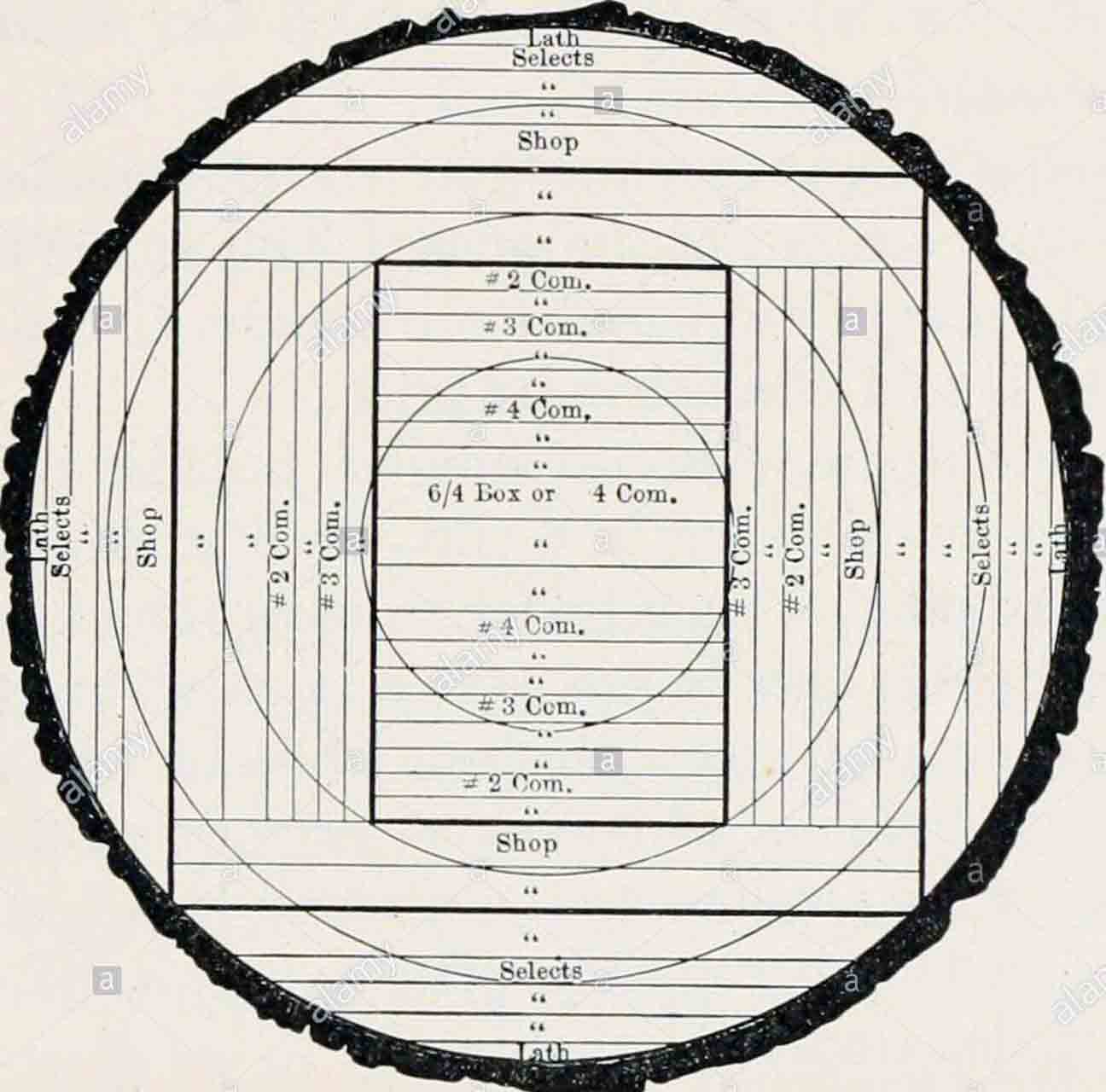

The logs ride along the log deck to the Circular Head Saw to determine the best possible cuts.

After leaving the Circular Saw, the Resaw cuts the top and bottom of the boards to give it the height or thickness of the board.

The Edger cuts the sides to give the board its width.

The Trimmer then cuts the boards to length.

The lumber moves along the Green Chain where it is stacked, banded and tagged.

All wood scraps are run through the chipper and turned into either wood chips or sawdust.

After the lift of lumber leaves the Green Chain, it is brought to the Dry Kiln to remove moisture from the boards.

After that, the lumber is taken to the Planer Mill, where it goes from rough to smooth lumber with a variety of different profile finishes.

The lumber is then transferred down to the retail store.

Customers either come into the store or place orders over the phone.

The requested lumber is then loaded onto our trucks for delivery to the customers.

Every load is checked for accuracy before it leaves the yard, as you can see, even the Bear knows how important Customer Service is here at N.C Hunt Lumber!

None of this would ever be possible without our Amazing Team!